Your 5-axis CNC machining service

Shorten lead times, reduce setups, and manufacture highly complex parts with 5-axis CNC machining—where speed meets precision.

What is 5 Axis CNC Machining

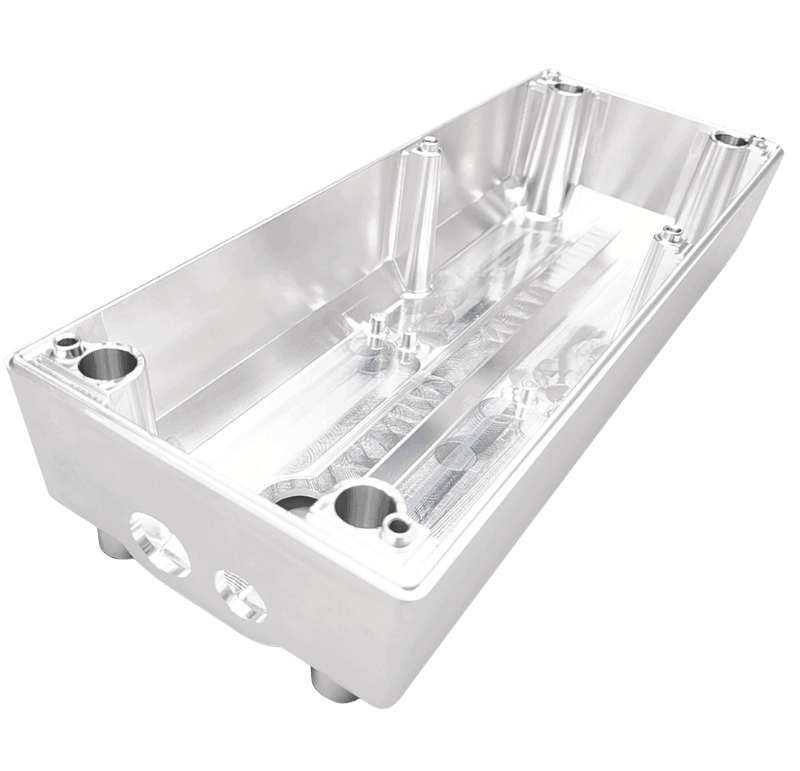

5-axis CNC machining is an advanced subtractive process that uses high-speed cutting tools similar to drills to precisely remove material from a workpiece. Unlike typical 3-axis CNC machines, which are limited to linear motion along the X, Y, and Z axes, 5-axis CNC machining includes two additional rotational axes (called A and B axes) on the X and Y axes. These additional axes enable the cutting tool to access a wider area on the workpiece from all angles, thereby increasing machining flexibility and accuracy.

5-axis CNC machining has changed the manufacturing landscape, enabling parts to be completed in one setup, greatly reducing setup and repositioning costs. Through intelligent programming, rigorous testing of data paths and optimization of tool paths before production ensures excellent efficiency and accuracy during machining.

Why TIRAPID is ideal for 5-axis CNC machining parts

Our fast response time coupled with outstanding customer service makes us the first choice for customers with precision manufacturing needs. Our reliable 5-axis machining services enable us to move your project forward, regardless of its complexity or size. With the ability to handle a large number of custom manufacturing projects and machining requirements, TIRAPID is your ultimate solution.

TIRAPID is proud to be ISO 9001 certified, which is a testament to our unwavering commitment to providing high-quality parts. This certification reflects our meticulous attention to quality and our continuous efforts to improve our services to ensure a seamless and worry-free experience for our customers.

5-axis CNC parts often feature custom features, intricate designs and complex geometries. With 9 years of experience in providing project-critical precision machined parts to a wide range of industries, you can trust TIRAPID to meet and exceed your expectations.

全面的维度报告

严格的 EN3.1 材料认证

平均交付时间为 1 - 2.5 周

首件检查报告 (FAIR)

公差在 ±0.05 毫米以内或更佳

通常比原计划提前两天交付

TIRAPID's various materials

We have a large network of trusted partners equipped with advanced CNC machinery, allowing us to produce exactly what you need, when you need it. The integration of Computer Aided Manufacturing (CAM) opens up a world of possibilities, allowing us to process a wide range of materials with the highest precision and efficiency.

Please see our comprehensive list of materials. If the material you are looking for is not listed here, please feel free to contact us to discuss your specific requirements.

Surface finishing options for 5-axis machined parts

加工表面

喷砂

阳极氧化 2 型表面处理

阳极氧化 3 型表面处理

我们的运作机制

At TIRAPID, we go beyond machining—we offer free design reviews and DFM optimization to help you reduce costs, improve manufacturability, and shorten your development cycle.

Embark on your manufacturing journey today. Share your project details and one of TIRAPID’s experienced engineers will conduct an in-depth, personalized review of your requirements, ensuring every technical aspect is carefully evaluated for precision and efficiency.

生产合作伙伴设施

High quality made in China

Efficient production

Absolutely excellent quality

案例研究:展示我们的成功故事

Our Auto Parts Partnership with Tesla

Our UAV Parts Collaboration with a Leading Drone Manufacturer

Our Marine Parts Manufacturing for a Global Shipbuilder

Trust the professionalism of TiRapid engineers

艾伦

凯文

戴维

杰克

安妮

艾米

TIRAPID 的技术能力让我感到放心,他们的专业建议对项目的成功至关重要。

米娅

专门的项目管理和支持

贝拉-梁

Galen Cui

杜美琪

Nick Zhai

Rea Tang

Zoey Yong

陈嘉怡

林富

Common Problems of 5-axis CNC Machining

Want a quote?

We typically provide quotations within 4–8 hours.

For a fast and professional response, please contact us at 📩 projects@tirapid.com or 📱 +86 13528252057 (WhatsApp).

What is the quote turnaround time ?

Most quotes arrive in your inbox within 8 hours. For larger batch orders, we guarantee a full response within 24 hours.

Do we have ISO 9001 certification ?

Yes, we are ISO 9001:2015 certified. If you would like, we can also share more details about our quality management practices.

What is our fastest CNC machining lead time ?

For small CNC projects involving Al6061, We can achieve extraordinary results. Since we have in-house stock of this material, we can start and complete fabrication in as little as 2 days, ensuring your project keeps moving quickly without compromising quality.

Will anodizing affect the thickness of the product ?

在阳极氧化领域,II 型是标准的变化。II 型阳极氧化的透明涂层厚度一般为 5 - 15 微米,彩色或有色涂层厚度为 10 - 25 微米。III 型阳极氧化通常被称为 "硬阳极氧化",厚度可达 20 - 80 µm。需要记住的一个有用的设计原则是阳极涂层的 50% 低于原始表面,50% 高于原始表面。例如,12 µm 的涂层会使零件厚度增加 6 µm,这对于精确设计和装配的考虑至关重要。

What thread specification compatibility can be used ?

Our machining capabilities extend to a wide range of thread specifications. We expertly process ISO metric threads (e.g. M3, M6, etc.) as well as BSPT, BSP and UNF threads. This broad compatibility ensures that our machined parts can be seamlessly integrated into a wide range of components across a wide range of industries.

了解我们的各种制造工艺

数控加工服务

- 5 轴数控铣削加工

- 公差小至 ±.01 毫米(±.0004 英寸)

- 交货时间:3 个工作日起

5 轴数控加工

- 轻松加工复杂零件

- 加快生产速度,更快交货

- 可轻松处理长度达 600 毫米(24 英寸)的零件。

数控铣削服务

- 长度最大可达 3000 毫米(118 英寸)

- 50 多种材料选择(金属和塑料)

- 擅长超薄壁部件生产

数控车削服务

- 最小部件尺寸小至 2 毫米

- 表面光洁度可达 Ra0.6

- 为小批量生产量身定制

表面处理

- 通过 72 小时盐雾测试

- 超过 21 种表面处理选项

螺杆加工服务

- 擅长小型、精密、复杂部件

- 自动化确保质量和效率

- 非常适合航空航天、医疗和电子领域

线切割加工服务

- 可实现无毛刺的清洁效果

- 轻松制作复杂细致的形状

- 降低复杂部件的制造成本