ラピッドシートメタルプロトタイピング

Rapid Sheet Metal Prototyping is the fastest solution for converting designs into products. Production is fast, raw materials are readily available, and the equipment used is versatile. Parts from simple to complex structures can be produced in less than 48 hours.

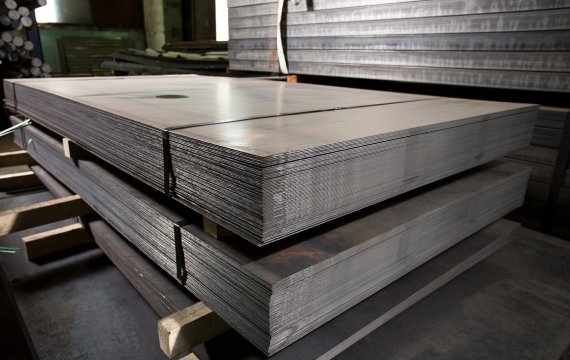

From one piece to dozens of pieces is the most suitable quantity for rapid prototyping. Catering to a wide range of metal raw materials such as aluminum, brass, copper, stainless steel and cold rolled steel.

Just a Few Steps!Get Your Sheet Metal Prototyping

- Manufacturability (DFM) analysis

- Design machining program and calculate material size

- Prepare production cutters and tools

- Inspection of raw material dimensions

- Start production and commission the first sample

- Continuous inspection during production

- Inspection of first piece samples

- Finished product inspection before shipment

- Produce product test reports

- Design suitable packaging program

- Finish packing and packaging

- Deliver to courier company and arrange shipment

Options for Sheet Metal Materials

Thin sheets with a material thickness of 0.24inch (6mm) or less are suitable for sheet metal prototyping, common materials such as:

Sheet Metal Surface Finishing

A wide range of surface finishing technologies are available:

-

Painting

-

パウダーコーティング

-

Electroplating Zinc

-

Silk Screen Printing