In manufacturing, CNC machines have become essential tools due to their precision in computer-controlled machining. These machines excel across various industries, ensuring high consistency and quality in mass production.

In this article, we will explore the various types of CNC machines in detail to help you better understand their functions and applications.

What is CNC Machine?

CNC machine are a type of processing equipment controlled by computer programs that can automatically complete operations such as cutting, forming and drilling of materials. It accurately controls the position and movement of the tool by inputting instructions, making the processing process more sophisticated and efficient.

The automation characteristics of CNC machine tools not only reduce manual intervention, but also improve the consistency and accuracy of production. They are widely used in various fields from mechanical parts manufacturing to complex mold processing.

15 Types of CNC Machines

1. CNC Milling Machine

CNC Milling machines are usually categorized into two types, vertical and horizontal, with vertical milling machines being suitable for machining parts with intricate details, while horizontal milling machines are suitable for machining deep grooves and large-sized parts.

They are widely used in the manufacturing industry for producing various parts with complex shapes, such as automotive parts, molds, rapid prototyping, and consumer products.

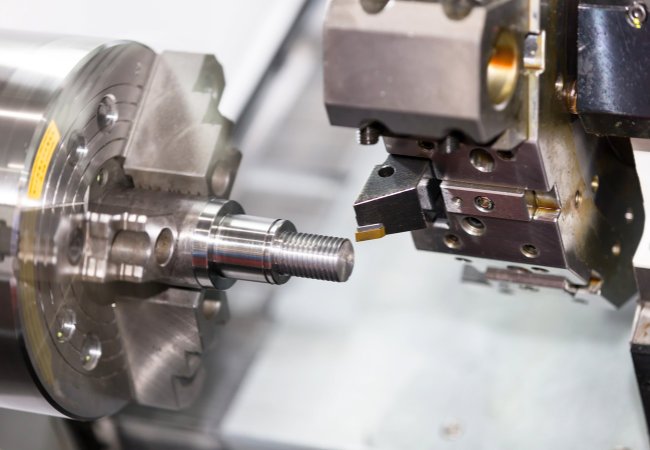

2. CNC Lathe Machine

CNC lathes remove material by rotating the workpiece and removing it with a stationary single-point cutting tool. They are particularly suitable for machining symmetrical cylindrical parts such as shafts, bolts, and pipe fittings.

Lathes can perform a variety of operations such as cutting, drilling, and thread turning to provide high precision machining results. Commonly used in manufacturing for shaft parts, gears, flanges, and a variety of components that require high precision and surface finish.

3. CNC Drilling Machine

CNC drilling machine is a computer-controlled device that uses a rotating drill bit to accurately drill holes in materials. Unlike traditional drilling machines, CNC drilling machines can operate automatically according to preset programs to ensure that the position and size of each hole meet high precision requirements.

It is mainly used in the production of parts that require high-precision holes. For example, it is often used to process the center hole of gears, through holes on mechanical shafts, and connection holes of various parts.

4. CNC Laser Cutting Machine

CNC laser cutting machines utilize a focused laser beam to cut materials, enabling high precision and complex shapes. With high cutting precision and surface quality, laser cutting is suitable for both non-metallic and metallic materials.

It is commonly used for fine processing of chassis shells, automobile manufacturing, electronic products and decorative artwork.

5. CNC Plasma Cutting Machine

CNC plasma cutters use high-temperature plasma to cut metal and are suitable for cutting conductive materials of greater thickness. Compared with laser cutting, plasma cutting is faster, but the surface quality is slightly inferior.

Commonly used in the manufacturing industry for steel structures, sheet metal processing and repair.

6. CNC Waterjet Cutting Machine

CNC waterjet cutting machine utilizes high-pressure water flow with abrasive to cut materials, and is suitable for materials that do not resist high temperatures, such as plastics, composites, and glass.

It can accurately cut a variety of materials without creating a heat-affected zone. It is widely used in automobile manufacturing, stone processing and building decoration.

7. CNC Grinding Machine

CNC grinding machines are used to precisely remove workpiece material by means of rotating grinding wheels, and are used to obtain extremely high surface finish and dimensional accuracy, and are suitable for machining metal parts with high hardness.

Grinding machines are often used for the finishing of parts and are particularly suitable for hardened steel parts and magnetic metal materials.

8. CNC Carving Machine

CNC engraving machine is usually used to process softer materials, such as wood, plastic and foam. It has a large working table and automatic tool change function, which can process complex patterns and shapes quickly.

CNC engraving machine is widely used in the fields of woodworking, furniture manufacturing, advertising signs and model making.

9. CNC EDM Machine

CNC EDM machines are capable of machining very hard metals or complex shapes by eroding the material through electrical discharge. EDM is often used to create micro holes, narrow grooves and other features that are difficult to machine by traditional methods.

EDM is commonly used for the machining of complex parts in mold and die making, aerospace and precision machine building.

10. CNC Gear Hobbing Machine

CNC Gear Hobbing Machine is a machine used to cut gear teeth by using a rotating cutter (hob) to gradually form precise gear teeth on the workpiece. Widely used in automotive, machinery and equipment, heavy machinery and other industries.

It is particularly suitable for the production of high-precision gears, sprockets and worm gears and other parts. Its advantage lies in its ability to realize efficient mass production of complex tooth shapes and ensure the accuracy and consistency of each gear.

11. CNC Brake Press Machine

CNC bending machine is a machine controlled by CNC system for accurate bending of metal sheets. It is mainly used in manufacturing industries, such as sheet metal processing, automotive parts manufacturing, home appliance shells and other fields.

CNC bending machine can accurately control the bending angle and shape, improve productivity and ensure product consistency, is the key equipment for the production of complex sheet metal parts.

12. CNC Boring Machine

CNC Boring Machine is a high-precision machine for machining internal holes, which realizes hole reaming, precision machining and dressing by controlling the tool position and feed through the CNC system.

It is widely used in the aerospace, mold making and heavy machinery industries for machining engine blocks, bearing housings and other bore parts that require high precision. The advantage of CNC boring machine lies in its high accuracy and repeatability, which is suitable for mass production of highly demanding hole machining tasks.

13. CNC Band Saw Machine

CNC band saw machine is a kind of machine using continuous circular band saw blade for cutting, CNC system controls the sawing path and feed speed, suitable for cutting materials such as metal, wood and plastic.

It is mainly used in the manufacturing industry, especially where high volume and high precision cutting is required, such as metal processing, woodworking and plastic products processing. Advantages of CNC band saws include high-efficiency cutting and less material waste, suitable for precision and complex shape cutting tasks.

14. CNC Punching Machine

CNC Punching Machine is a machine tool that punches and shapes metal sheets by controlling the punch through a CNC system, which is widely used in sheet metal processing, home appliance manufacturing and automotive industry. It is capable of efficiently realizing punching and cutting operations for complex shapes, ensuring consistency and high accuracy of parts.

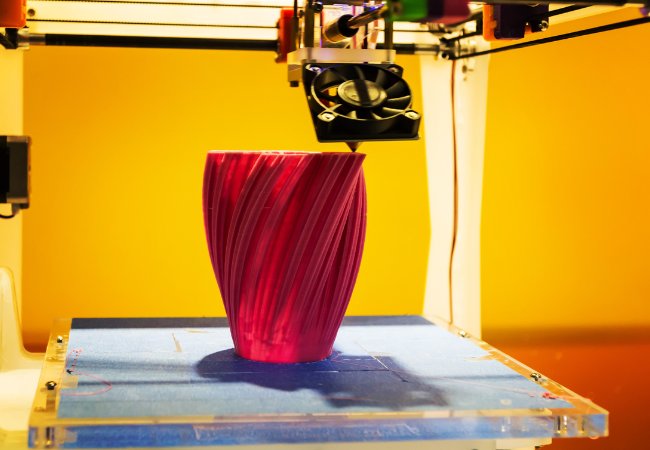

15. CNC 3D Printer

CNC 3D printers are a fusion of CNC and additive manufacturing technologies that create complex parts by stacking materials layer by layer. Widely used in areas such as prototyping, mold making and medical devices, they are capable of rapidly producing parts with complex structures and geometries.

The advantages of CNC 3D printers lie in their high precision, material versatility, and flexibility, making them suitable for the production of customized, small batch, and intricately designed products.

Advantages and Disadvantages of CNC Machining Technology

| Dominance | Inferior |

| High precision and consistency | Higher equipment costs |

| Improvement of production efficiency | Requires specialized programming and operating skills |

| Reducing the risk of human error | Larger initial investment |

| Ability to process a wide range of materials | Complex shape processing may require high-end equipment |

| Suitable for 1-piece prototypes and

high volume production |

Higher maintenance and repair costs |

| Reduced processing time | Degrees of freedom may be limited for some complex designs |

| Versatile finish options | Complexity of control systems and drive systems may limit equipment capabilities |

| High degree of automation and reduced labor requirements | Old or low-end equipment may have limited performance |

How to Choose the Right CNC Machine

- Suitability of Processed Materials

When selecting a CNC machine, the first step is to evaluate its suitability for the type of material being machined. Different materials (e.g. high hardness alloys, non-ferrous metals, engineering plastics, etc.) have different requirements for cutting forces, tool life and surface quality.

Therefore, choose a machine that offers the appropriate spindle power, cutting speed and cooling system to ensure efficient and high-quality machining.

- Machining Accuracy and Repeatability

For precision manufacturing, the machining accuracy and repeatability of a CNC machine is critical. Selection requires consideration of the machine’s linear and rotary axis accuracy, machine rigidity, thermal stability, and feedback system resolution.

These factors determine the machine’s ability to maintain accuracy over extended periods of operation, especially in applications where micron-level tolerances are required.

- Productivity and Processing Efficiency

In a high-volume manufacturing environment, the productivity of a CNC machine is a key indicator. The machine’s feed rate, tool change time, automation (automatic loading systems), and ability to parallelize multiple processes are evaluated.

Efficient machines reduce cycle times, maximize productivity, and maintain consistent machining quality across volume production.

- Versatility and Process Integration

Modern manufacturing requires CNC machine tools with the versatility to integrate multiple processes (e.g. milling, drilling, turning, etc.) to minimize changeover and process transition times. Multi-functional machines not only increase flexibility, but also improve accuracy and reduce error accumulation by reducing the number of workpiece clamping.

Therefore, CNC machines that support multi-process integration should be selected to meet the machining needs of complex parts.

- Cost-effectiveness and life-cycle Cost Analysis

When selecting a CNC machine, in addition to the initial cost, it is also necessary to fully evaluate the cost factors throughout the entire life cycle.This includes energy consumption, maintenance and upkeep costs, parts replacement costs, and lost production downtime of the machine.

By analyzing these factors, companies can optimize their total cost of ownership by selecting the machine that provides the highest return on investment over the long term.

- Availability of After-sales Support and Technical Services

The reliability and uptime of CNC machine has a direct impact on productivity, so the quality of after-sales support and technical service is critical. When selecting a machine, assess the level of technical support offered by the manufacturer, response times, the stability of the spare parts supply chain and the availability of remote diagnostic and maintenance services.

Quality after-sales service minimizes downtime and ensures that the machine is always in optimal working condition.

Conclusion

CNC machines have become indispensable tools in a wide range of industries due to their superior precision and efficient machining capabilities. They are capable of meeting a wide range of machining needs, from simple to complex, and are widely used in all areas of manufacturing. As technology continues to advance, the types and functions of CNC machines are expanding, bringing more possibilities to modern manufacturing.

By understanding the different types of these machines and their applications, engineers and manufacturers are able to more effectively optimize their production processes, improve product quality, and stay ahead of fierce competition in the marketplace.

FAQs

1. Are CNC machines suitable for small batch production?

CNC machines are ideally suited for small batch production, especially for parts that require high precision and complex geometries. With automated programming, CNC machines can quickly switch production tasks and adapt to the needs of different batches.

2. What types of multi-axis CNC milling machine are there?

Common multi-axis CNC milling machine include: 4-axis CNC machine,5-axis CNC machine,6-axis CNC machine,7-axis CNC machine,9-axis CNC machine,12 axis CNC machine.

3. What are the most frequently used CNC machine in manufacturing?

The three most commonly used CNC machines are the CNC milling machine, the CNC lathe, and the CNC laser cutting machine.